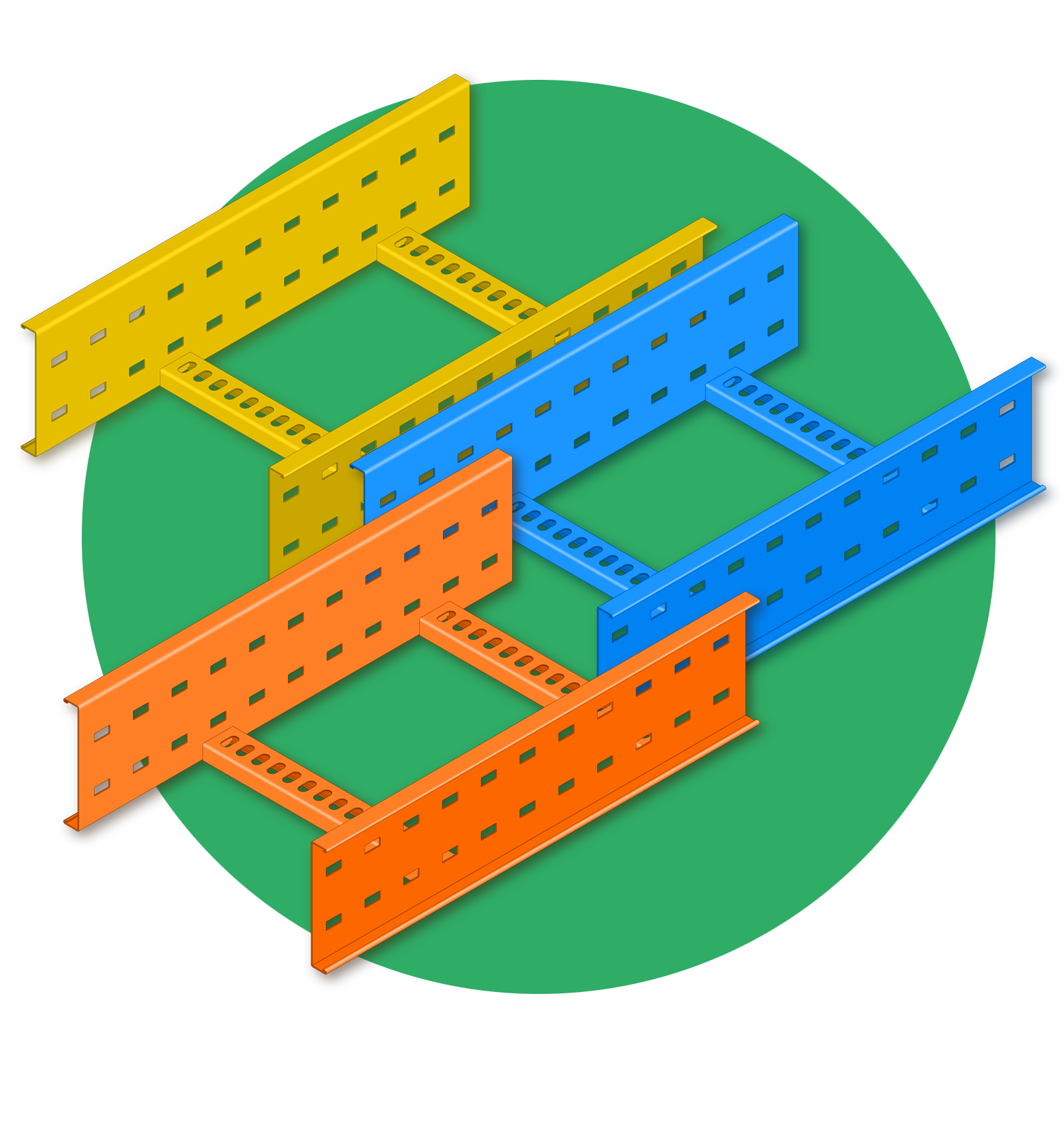

Our Cable Management Systems

Powder coating in any RAL colour

Did you know that you can have all our cable support systems powder coated in any RAL colour upon request? A powder coating not only makes the system more aesthetically attractive or more eye-catching, it also provides extra protection against external influences, such as corrosion and damage.

FAQ's about Cable Support Systems

There are different types of cable support systems, including:

- Cable trays: Closed or perforated trays, ideal for bundling and protecting cables from dust and mechanical influences.

- Wire trays: Light, open systems that are mainly used in IT environments and light industry. Easier to keep clean due to their open structure.

- Ladder tracks: Robust systems suitable for heavy cables and long spans, often used in the (chemical) industry and energy supply. Depending on the finish, suitable for indoor and outdoor use in (heavy) corrosive environments.

When installing a cable support system, it is important to consider:

- Load: Make sure the system is suitable for the weight of the cables.

- Mounting: Use appropriate suspension systems and spacers to prevent sagging or overloading.

- Accessibility: Plan the route to ensure easy maintenance and expansion.

- Safety: Keep sufficient distance from heat sources and sharp edges to prevent damage.

- Grounding: Depending on the system and application, proper grounding may be required.

The most commonly used materials are:

- Hot-Dip Galvanized (Carbon) Steel: Widely used because of its good price-quality ratio and rust resistance. Many of our products have a layer thickness of 60 to 70 µm; well above the required standard.

- Stainless Steel (SS): Ideal for corrosive environments such as food industry and chemical plants.

- Aluminum: Lightweight and rustproof, suitable for applications where weight is a factor.

The choice depends on the environment in which the system is installed and the specific requirements such as fire safety, chemical resistance and corrosion class.

There are several standards and guidelines that may apply, including:

- NEN 1010: Rules for the safety of electrical installations.

- IEC 61537: International standard for cable support systems.

- NEN-EN-ISO 1461: Standard for hot-dip galvanizing of steel cable trays.

It is important to check which standards apply within your sector and environment.

To ensure safe and efficient cable routing:

- Use separate ducts for data and power cables to minimize electromagnetic interference.

- Ensure sufficient space in the cable ducts so that cables are not too tight and can be easily added or replaced.

- Take heat development into account and prevent cables from being too close to heat sources.

- Use good quality brackets and fasteners to prevent sagging and damage.

- Create a good maintenance plan and ensure periodic inspection of the cable support systems.

Need help putting together your cable support system?

Do you have any questions about cable support systems or would you like personal advice?

Contact us and our experts will be happy to help you find the best solution for your project.